MSI's piezoelectric composite materials are an excellent choice for sonar applications. They provide high electro-mechanical energy coupling to water, air, plastics, composite materials and other low acoustic impedance media. Transducers made from piezocomposite are highly efficient and inherently broadband.

Injection molded piezocomposites offer the following advantages over conventional monolithic piezoelectric ceramics:

- Broad Bandwidth (Q < 3 typically)

- High Sensitivity

- High Source Levels

- Conformability for Curved Arrays

- Reduced Side Lobes

- Complex Shading Patterns

- Full Ocean Depth Capability

- Cost Effective Solutions

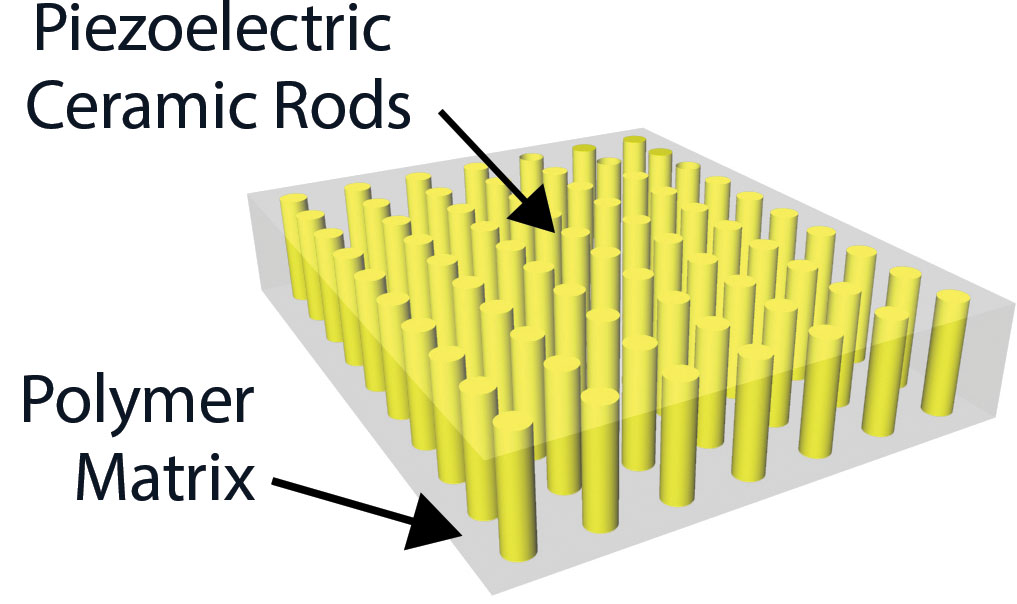

1 ‐ 3 Piezocomposite

- Piezoceramic rods in a polymer matrix act as homogeneous medium

- Many more design variables than solid ceramic to optimize performance

- Ceramic material

- Polymer material

- Volume fraction (amount of ceramic)

- Electrode pattern (aperture shape and array configuration)

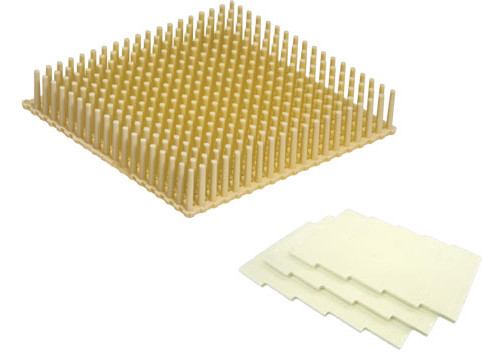

MSI's Injection Molded Piezocomposite

- High manufacturing rate - 30x faster than conventional dicing

- Excellent piezoelectric uniformity

- Standard pre-forms cover 17 kHz to 600 kHz

MSI's Applications

- Acoustic Communications (ACOMMs)

- Diver Detection

- Sidescan Arrays

- Multibeams (Bathymetry, Bottom Mapping)

- Curved Receivers and Projectors

- UUV Sensors

- Synthetic Aperture Sonars

- Forward Looking Sonars

Specializing in Custom Designed Transducers

Specializing in Custom Designed Transducers